Sustainability

Environmental Management System

EMS is a set of processes and practices that enable an organization to reduce its environmental impacts and increase its operating efficiency. The system includes the following programs:

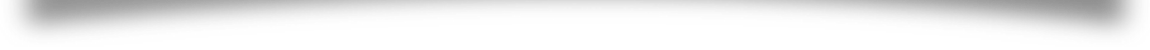

Water resources

Water consumption management to reduce consumption at three different stages of the brewing process. Each step requires specific actions:

Optimize the water use in Petropolis Group plants to achieve the Global Benchmarking Index (3.3 Hl / Hl beer), thus contributing to sustainable and profitable growth. Initiatives we promote:

- Regular training to operation workers: Conservation, Reuse and Recycling;

- Diagnosis, identification, implementation and follow-up (wort ballast water, rinse water, OD’s pre-rinse, sealing machines rinse, box washer);

- Technology to reduce water consumption in pasteurizers cooling towers;

- Optimization of consumption: Interconnection of the CIP return pipe from wort line to the rice washer, water from wort, etc.;

- Rain water harvesting and reuse: pavement washing / Alagoinhas and Itapissuma premises cleaning;

- Use of high efficiency faucets & flush valves.

Water consumption index*

*Liter of water per liter of beer produced.

Air emissions

Control and reduction of motor vehicles and boilers emissions through the following initiatives:

- Awareness Raising Sessions for workers;

- Quantitative analysis of boiler chimneys, own vehicle fleet and third-party fleet emissions

on a 6-month basis; - Deployment of emission reduction technologies;

- CO2 management to ensure surplus trading, lowering air emission;

- AMA Project: 198,029 tons of CO2 captured.

Air emissions compliance

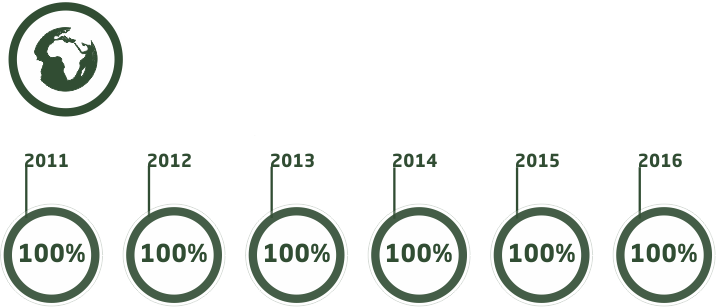

Solid waste

Solid waste management & disposal.

Petropolis Group seeks to minimize solid waste production, increasing its reuse and recycling. Currently,

99% of our waste is reused, preventing pollution and reducing the use of natural resources.

To achieve this goal, we deploy the following actions:

- Awareness Raising Sessions on waste reduction;

- Method of Disposing Non-Recyclable Waste, composting, co-processing, decontamination and refining;

- Waste Stream Monitoring;

- Reverse Logistics Operations deployed in our production plants and Distribution Centers (UND);

- Waste value adding projects developed in partnership with SENAI Faculty – Diatomaceous Earth,

Label Pulp and Sludge ETDI – Zero Landfill; - Inauguration in March 2015 of the Voluntary Delivery Station in Boituva: stimulating municipal selective collection and

supporting reverse logistics; - Reverse Logistics: 527 tons of glass, cardboard, plastic and aluminum separated for reuse.

% of recycled residues

Energy matrix

Reduction of electricity consumption in the production and administrative areas, through technology and awareness. To achieve this goal, we deploy the following actions:

- Energy Management Systems;

- Plant team to identify, deploy and monitor opportunities to reduce electricity consumption;

- Good practices to reduce electricity consumption & regular audits;

- Deployment of electricity consumption reduction technology (air extraction system, separate cooling systems);

- LED and natural lighting in Filling & Packaging lines and process areas;

- Natural ventilation, solar heating in locker rooms and air conditioning system with direct expansion system

cooled with ice water; - Renewable fuels: biomass in Boituva and Rondonopolis;

- In 2016, 29% of renewable fuels were used in our processes.